Sam Dinnat, E.I.

Mechanical Engineer & Economist

Aspiring Professional Engineer (EI Certification from Florida Board of Professional Engineers)

Learn more about my engineering design experience and projects, as well as what I hope to work on in the future.

Robotics Hardware Design · Senior Design Project · Freshman Design Project · 3D Printing Experiments · Robotics Programming Projects · Golf Club Design

Learn more about the engineering research I presented at the UL Academic Summit or the economics research I presented at the Federal Reserve in 2019.

Materials Science · Thermal Design · Mechanics · Econometrics

About Me

Professional Summary

Hello! I'm Sam Dinnat, a dedicated mechanical engineer. With degrees in Mechanical Engineering and Business Economics from Louisiana Tech University, I have a unique perspective on engineering challenges and problem-solving.I initially pursued a career in economics and finance, but my passion for design and engineering eventually led me to my true calling. After professional aptitude testing and career counseling, I returned to Louisiana Tech.Having graduated from the mechanical engineering program, I now work as an Engineering Services Intern at Walt Disney World. My career goal is to become an engineer in the themed entertainment industry, where I can apply my creativity and technical expertise to design, develop, and maintain cutting-edge rides, attractions, robotics, and animated figures.I have passed the Fundamentals of Engineering (FE Mechanical) Exam and am a licensed EIT (Engineer In Training) through the Florida Board of Professional Engineers. This puts me on track to become a licensed professional engineer (PE).

Personal Summary

I am originally from Louisiana. I married my wife, Lauren, in 2020. We have a 6-year-old beagle named Bleu who loves to play fetch!I enjoy pursuing various hobbies in my free time such as golfing, exercising, playing drums, hunting, and 3D printing. My career goal is to become an engineer in the themed entertainment industry, where I can apply my creativity and technical expertise to design, develop, and maintain cutting-edge rides, attractions, robotics, and animated figures.

The Ability Experience

As a member of Pi Kappa Phi fraternity, I am proud to support our philanthropy, The Ability Experience. Our mission is to promote empathy and understanding towards people with disabilities while developing our members into servant leaders. By providing hands-on community building, fundraising, and support to people with disabilities across the country, The Ability Experience is changing the way society views those with disabilities. I encourage you to click the link below and learn more about how you can support this important cause

Professional Experience

The Walt Disney Company, Disney's Hollywood Studios · Orlando, Florida

• Engineering Services Intern (June 2024 – Present)

In my role, I have gained extensive experience collaborating with mechanical technicians and engineering service managers to resolve attraction downtimes, ensuring the reliability and safety of ride systems. I have worked closely with planned work specialists to incorporate effective project management strategies into ongoing projects, contributing to their timely and efficient completion. My expertise extends to modeling and 3D printing replacement components using SolidWorks and maintaining 3D printers to support operational needs and minimize downtime. Additionally, I have mapped and assigned asset numbers to safety-critical assets, including light poles, across the property, ensuring they were properly documented on job plan maps. This attention to detail allowed technicians to perform safety testing and uphold guest safety standards accurately. Each week I pull and analyze key performance indicator reports that show how the different departments are trending in their management and timely completion of work orders. These reports are shared at the director level.All opinions and work shown on this portfolio are my own and not the work, view, or position of the company.

Boardwalk Robotics · Pensacola, Florida

• Mechanical Engineering Intern (June 2023 – August 2023)

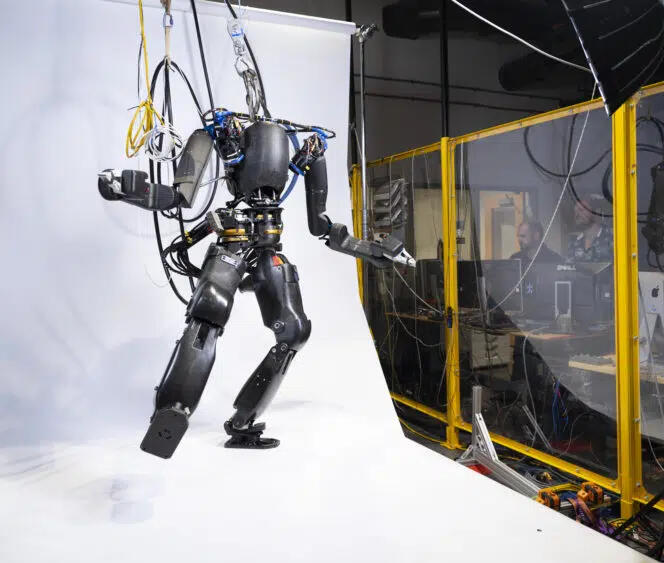

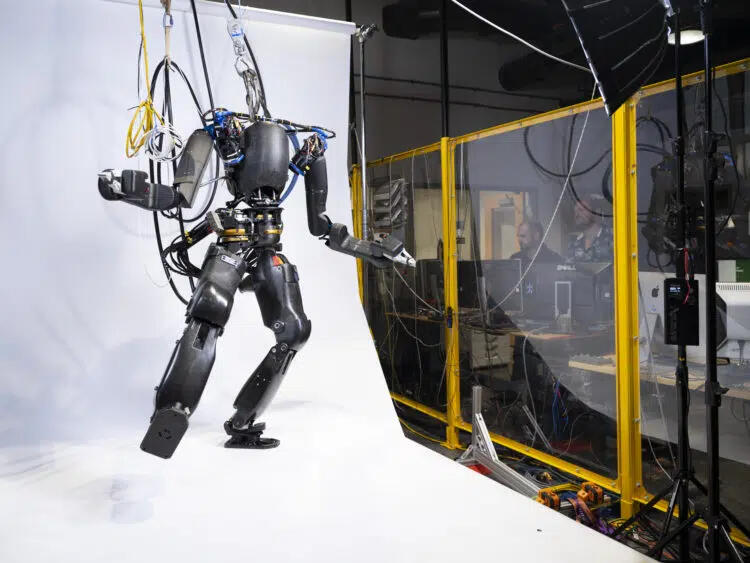

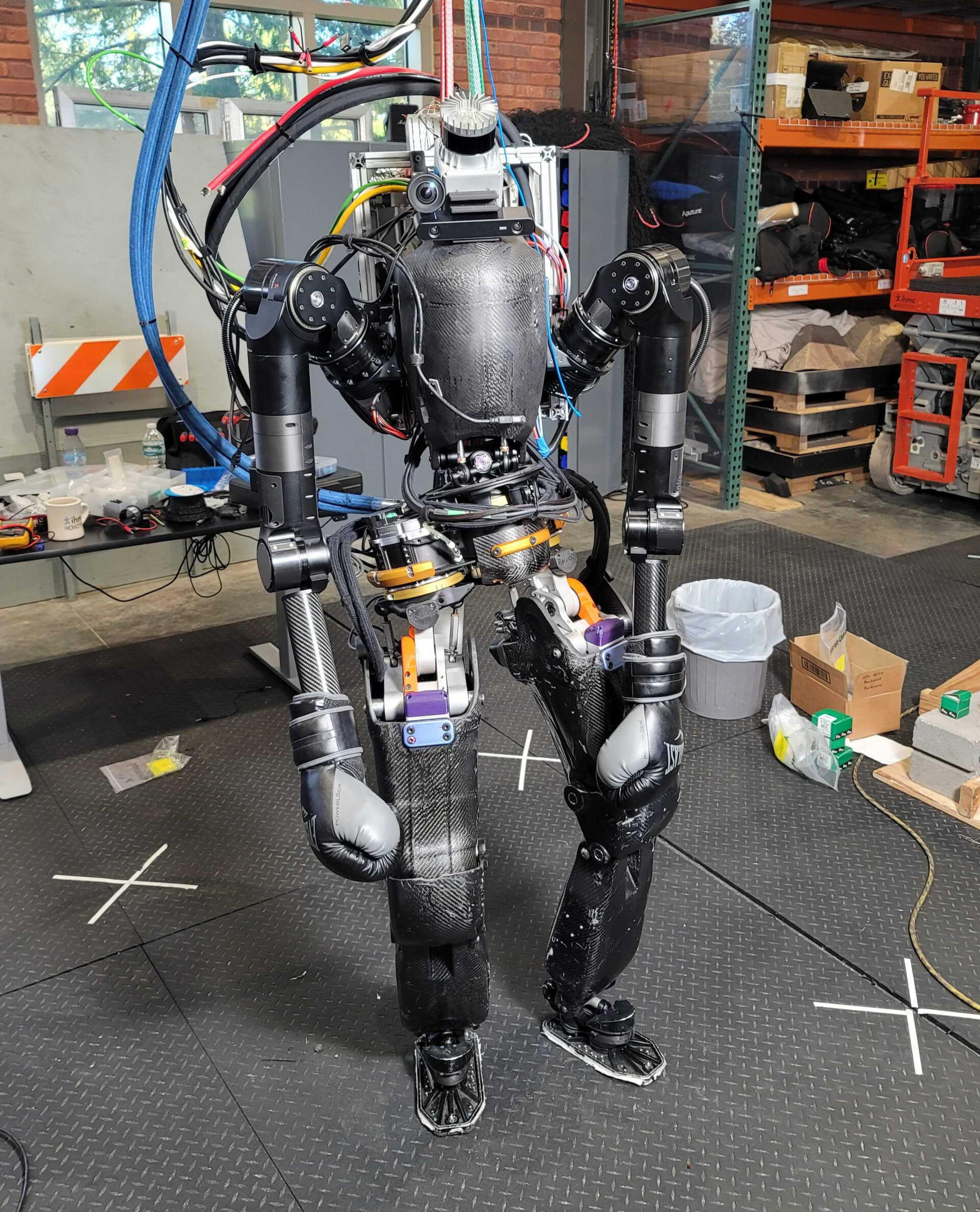

During this internship, I was able to continue working on the Nadia Humanoid robot platform through collaboration with IHMC. My main project for the summer was designing hardware to help transition Nadia to a fully onboard hydraulic power unit (HPU) and battery that were both designed in-house. Bringing the HPU on board is a vital step towards Nadia operating outside of a lab environment. I researched and tested components for the in-house HPU, contributing to enhanced system reliability and efficiency.

I also utilized my additive manufacturing skills to fabricate new perception mounts using carbon fiber-filled nylon 3D printing filament. This material enhanced the structural integrity of the mounts while reducing the overall weight.

Institute for Human and Machine Cognition (IHMC) Robotics Lab · Pensacola, Florida

• Mechanical Engineering Intern (June 2022 – August 2022)

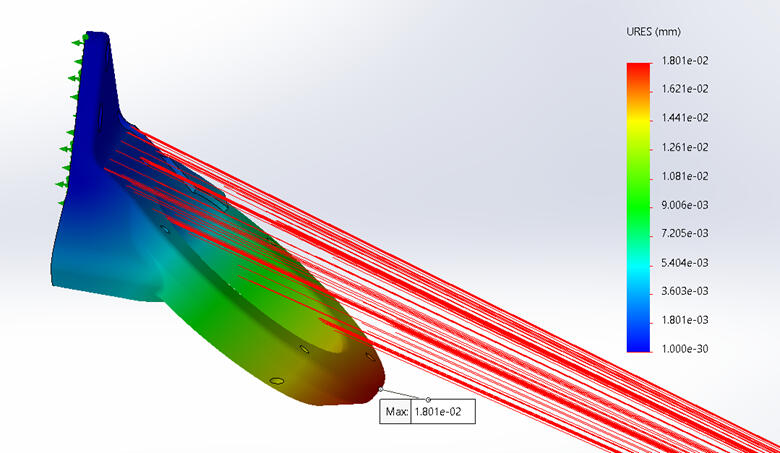

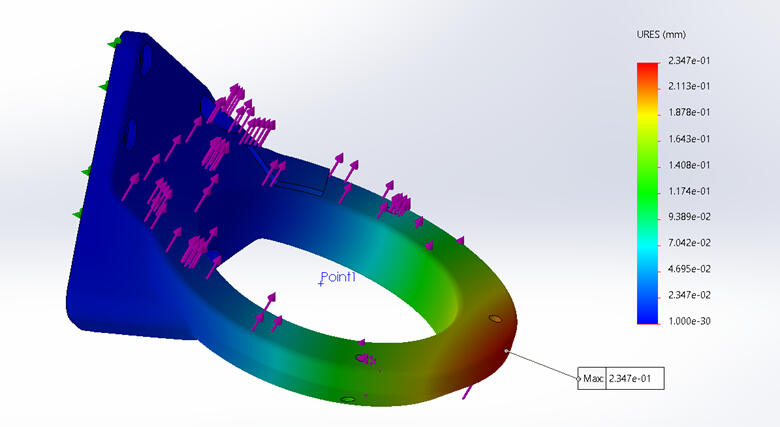

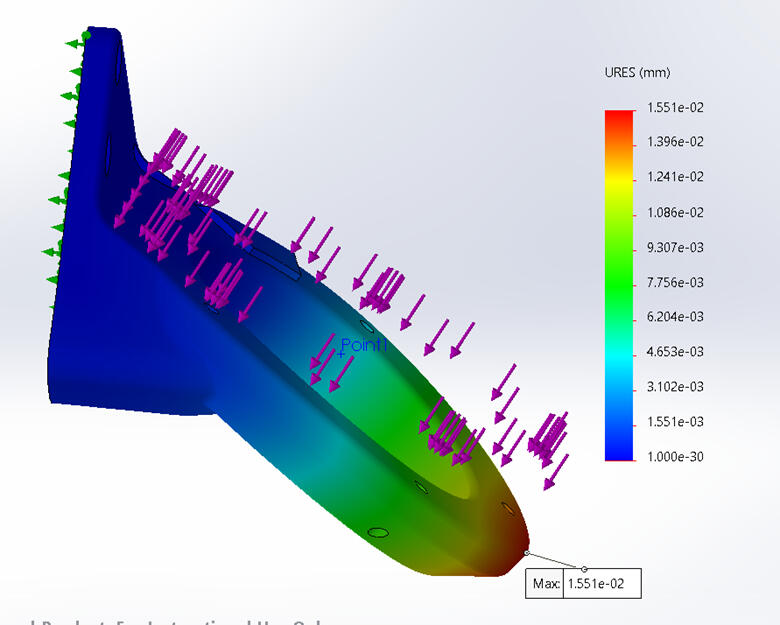

As a Mechanical Engineering Intern at IHMC Robotics, I was a member of the team responsible for designing, fabricating, and assembling hardware components for humanoid robots. During my summer internship, I contributed to the design and fabrication of various hardware pieces for the Nadia humanoid robot. To ensure the robustness of each component, I conducted finite element analysis (FEA) using Solidworks, testing them under different loading conditions.

My expertise in additive manufacturing techniques allowed me to 3D print components and build a full-scale mockup of the Nadia Humanoid Robot. Additionally, I gained experience in facilities engineering as I routed water lines and high-voltage power to Nadia's hydraulic power unit in the robotics lab.

My experience at IHMC Robotics provided me with important principles of mechanical design and a broadened perspective on the various fields involved in designing and building robotics platforms. As a result, I am equipped with the skills and knowledge to make significant contributions as a mechanical engineer.

Louisiana Tech University · Ruston, LA

• Research Assistant (September 2023 - May 2024)

In this position, I worked under Dr. Arden Moore in The Multiscale Energy Transport and Materials Laboratory at the Louisiana Tech Institute for Micromanufacturing.My project continued research from a past Master's student on utilizing the shape memory effect exhibited by 3D-printed PLA in a thermal switch. I was able to take the findings from this student's research and construct a completely passive thermal switch using a 3D printed shape memory polymer as the switching device. This research involves materials science, mechanical design, thermal design, and 3D-printing research.

Louisiana Tech University · Ruston, LA

• Research Assistant (October 2021 – September 2023)

As an Engineering Research Assistant, I worked under the guidance of Dr. Shawn Chen to study the plastic behavior of complex concentrated alloys using molecular dynamics software, LAMMPS. This atomistic research has far-reaching applications in a variety of industries, making it a critical study for fundamental mechanistic understanding and structural design of CCAs.

I was honored to present this research at the Louisiana Tech Undergraduate Research Symposium, and even more so to represent Louisiana Tech at the University of Louisiana System Academic Summit.

My team was also researching new, high-capacity solid-state electrolyte batteries to address the challenges of aerospace power and energy storage. Our collaboration with partners at NASA's Glenn Research Center and Jet Propulsion Lab, as well as General Motors and IBM, will ensure that the batteries are not only safe but meet the rigorous demands of future space missions.

This position has allowed me to deepen my understanding of the engineering research process and materials science, both of which are critical skills for success in the field of mechanical engineering.

Lockton Dunning Benefits, Lockton Companies · Dallas, TX

• Financial Analyst (March 2020 – November 2020)

As a financial analyst, I worked closely with top-level executives, including the CEO, and contributed to Lockton's growth and success. I evaluated medical insurance plans, conducted financial analyses, and completed benchmark assessments for Lockton's client mergers and acquisitions as well as client prospecting. In addition, I provided analytical support to upper-level management on various projects, leveraging my analytical and quantitative skills to deliver actionable insights.Lockton Dunning Benefits, Lockton Companies · Dallas, TX

• Benefits Analyst (December 2019 – March 2020)

At Lockton Dunning, I collaborated with five cross-functional teams to coordinate the completion of over 40 trend reports every month. I collected and analyzed financial data, prepared presentation materials for client meetings, and assisted with expense reporting and other related reports. I also developed a standardized trend reporting process and a training program for new benefits analysts, resulting in a 40% reduction in the time needed to complete monthly reports.

In just three months, I was promoted to a financial analyst position working with the CEO. My analytical skills and attention to detail helped support the company's success in meeting the needs of clients and achieving business objectives.United States Senate, Office of Senator Bill Cassidy, M.D. · Washington, DC

Intern (July 2019 – August 2019)

As a summer intern for United States Senator Bill Cassidy in 2019, I conducted extensive research on diverse topics of interest to the Senator and his staff. Specifically, I worked on a major project examining the military implications of China's Belt and Road Initiative, and explored asset recycling opportunities in the United States, following a meeting with the Australian Ambassador to the United States, Joe Hockey. In addition to conducting research, I also fostered positive relationships with Louisiana constituents. This experience allowed me to gain valuable insights into the legislative process and connect with professionals from across the country.

Pan American Engineers, LLC · Alexandria, LA

• Engineering Intern (June 2017 – September 2017, June 2018 – September 2018)

As an intern at Pan American Engineers during the summers of 2017 and 2018, I worked on a range of projects under the guidance of the CEO and CFO. My responsibilities included utilizing data analytics to conduct a market analysis for the State of Louisiana Office of Community Development Disaster Recovery Unit, where I determined the maximum amount of assistance per square foot of housing that the state could provide through reimbursements as relief for natural disaster damages. Additionally, I provided support for senior engineers and conducted extensive research on various topics in the field of mechanical engineering.

Education

I am a highly driven individual with a Bachelor of Science degree in Business Economics, graduating magna cum laude with honors from Louisiana Tech University in November 2019. I am currently pursuing my second bachelor's degree from the same institution in Mechanical Engineering, with a strong passion for becoming a design engineer.My academic curriculum is complemented by a range of classes in related fields, including computer science, industrial, and environmental engineering, to expand my skillset and stay up-to-date with the latest developments in the industry. With this diverse academic background, I am well-equipped to tackle the most challenging engineering problems.Degrees:

College of Engineering and Science

Bachelor of Science

Major: Mechanical Engineering

GPA: 3.975 · Louisiana Tech Honors CollegeCollege of Business

Bachelor of Science

Major: Business Economics

GPA: 3.85 · Louisiana Tech Honors College

Skills and Certifications

As a mechanical engineer, I am committed to constantly expanding my skill set and staying up-to-date with the latest technologies. I am a certified Engineering Intern (EIT) through the Florida Board of Professional Engineers, a crucial step in my journey towards becoming a licensed Professional Engineer.My Certified Solidworks Associate Certification evidences my proficiency in mechanical design.In addition to this, I am actively pursuing proficiency in various coding languages such as Python, which will enable me to pursue innovative projects in the fields of artificial intelligence, machine learning, and augmented reality. I am currently working on enhancing my skills through a course on Python Fundamentals on DataCamp.com.Some of my current skills include:

• 3D Computer-Aided Design (Solidworks - Certified Solidworks Associate, OnShape)

• 3D Printing, Additive Manufacturing, Prototyping, Mockup Development

• Programming, Development, and Data Science (Python, Matlab, Linux, R, C, C++)

• Molecular Dynamics Software (LAMMPS)

• Microsoft: Word, Excel, PowerPoint, Outlook

Leadership and involvement

Pi Kappa Phi Fraternity

Treasurer

• Managed a $100,000+ yearly budget, and facilitated the planning of a new chapter house

Standards Board

• Enforced Chapter Code of Conduct, Risk Management Policy, and University Rules and RegulationsPi Tau Sigma (Mechanical Engineering Honor Society)American Society of Mechanical Engineers (ASME)Aerospace Engineering ClubTheme Park Engineering and Design ClubStudent Government Association

Senator

• Drafted and voted on bills and resolutions on behalf of the students I represented

• Served as a Student Representative on Louisiana Tech’s Strategic Planning Committee

Supreme Court Justice

• Interpreted the SGA Constitution to determine the constitutionality of certain SGA actionsCollege of Business

Dean’s Advisory Council

• Met quarterly with College’s leadership to discuss pertinent issues and provide counsel

Ambassador

• Helped facilitate recruitment and retention events for the College of Business

Projects

Engineering Design Projects

Robotics Hardware Design (IHMC and Boardwalk Robotics)

During my two internships with IHMC and Boardwalk Robotics, I successfully designed and fabricated essential hardware that is now in active use on the robot, demonstrating my hands-on experience in mechanical engineering and ability to contribute to complex projects.

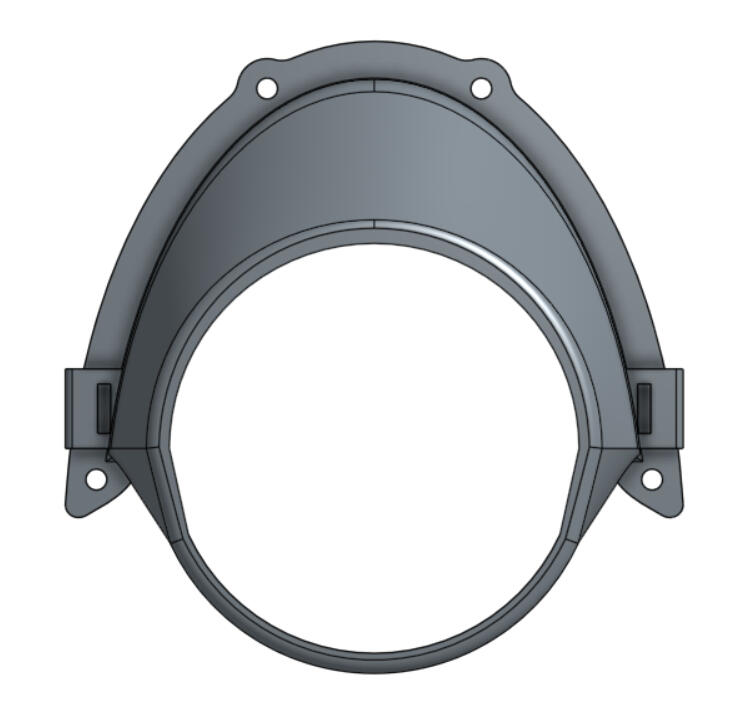

Cycloid Arm Mount:

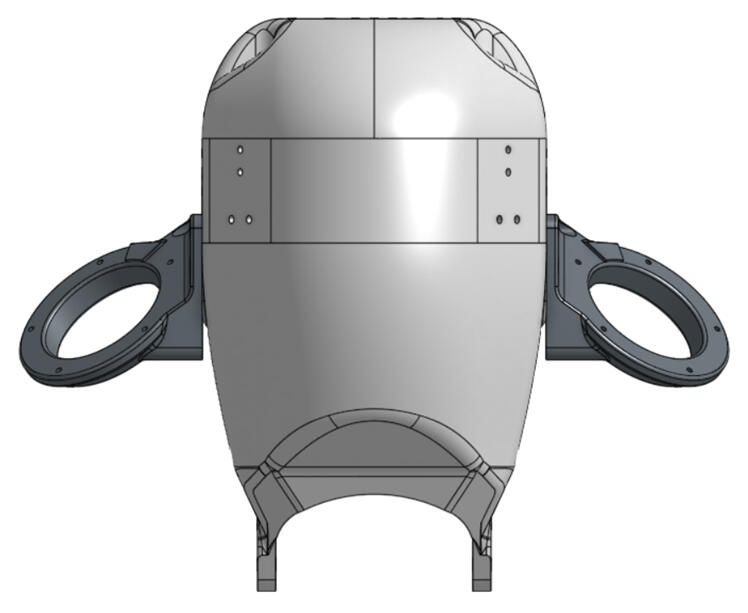

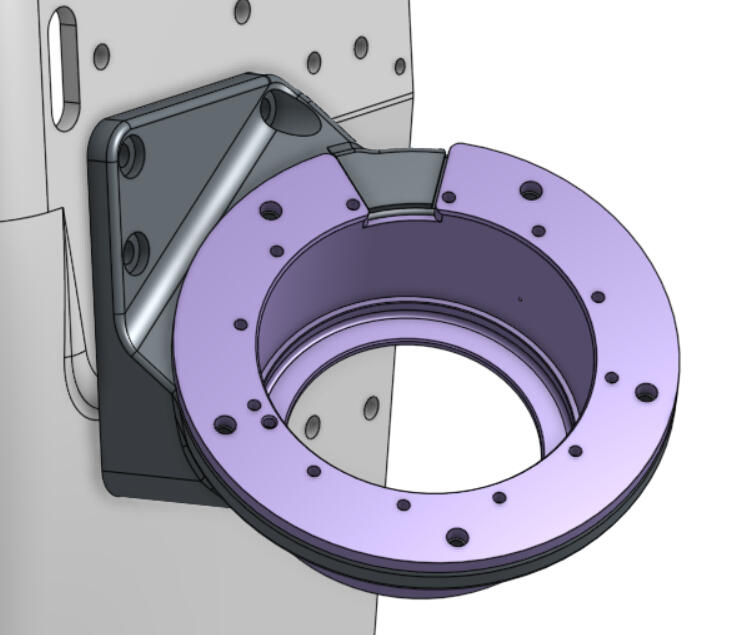

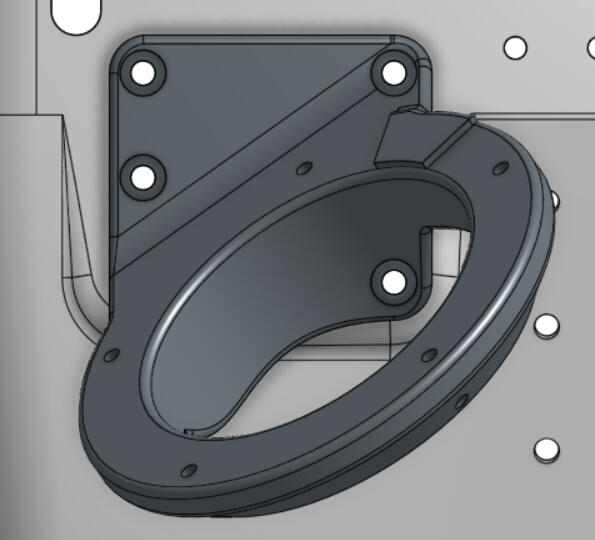

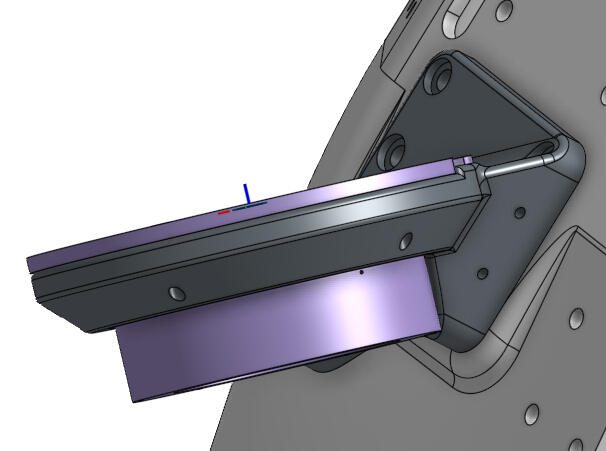

During my internship, the engineers at IHMC and Boardwalk Robotics were designing new cycloid motor arms for the Nadia Humanoid Robot, which will replace the t-motor arms. The new cycloid arms are much stronger than the t-motor arms, but will also be heavier.

I was tasked with designing a new piece to mount the new cycloid motor arms to the current Nadia torso. The torso will be redesigned in the future as Nadia moves further into version 2.0, but being able to attach the new arms to the current torso was crucial.Below are pictures of my design, which was done in OnShape. The purple part seen inside the mount in the bottom pictures is the large cycloid motor housing. The part was machined in August of 2023 and implemented on the robot in September 2023.

Below are some screenshots of the Finite Element Analysis (FEA) I conducted on the part using Solidworks Simulation. I tested a variety of different loading conditions that simulated what the robot would experience.

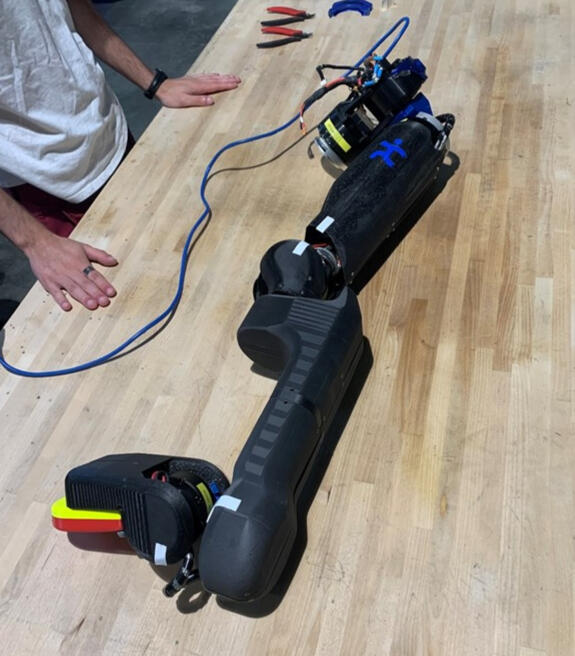

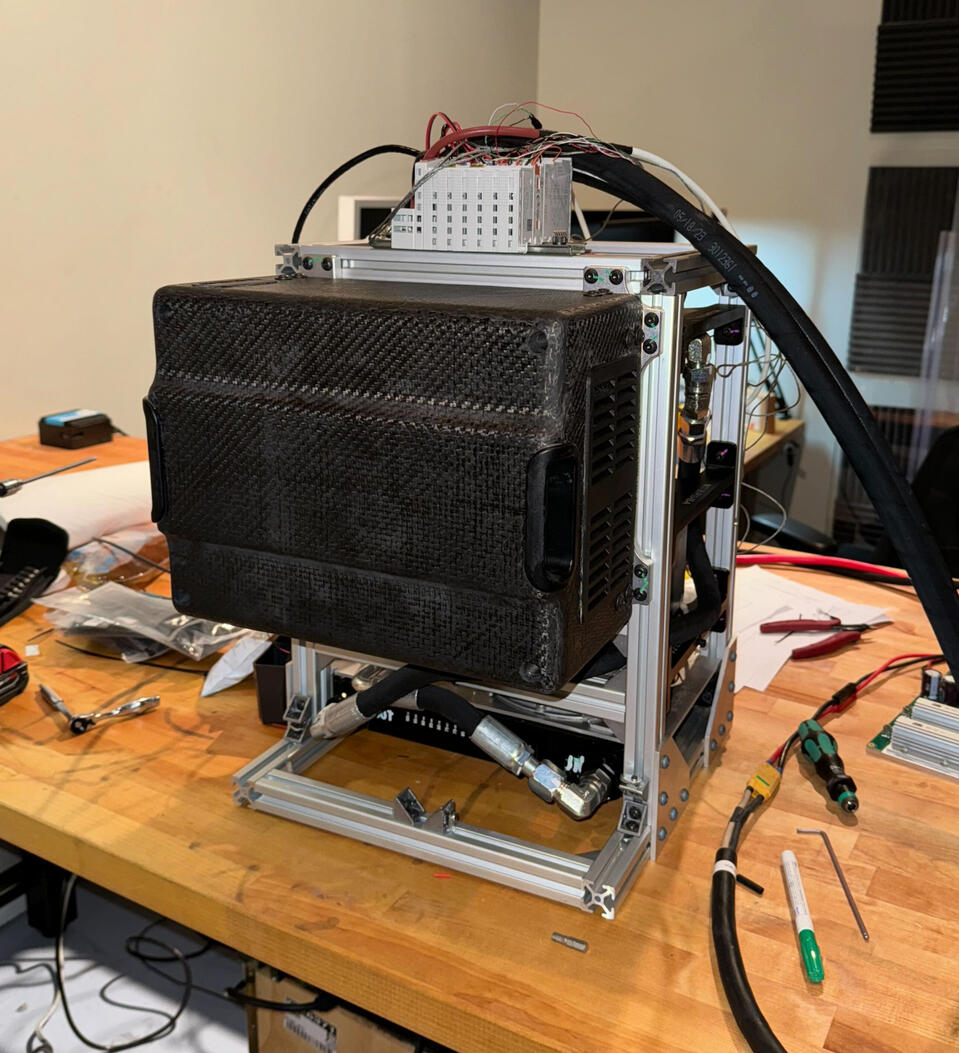

Onboard Hydraulic Power Unit:

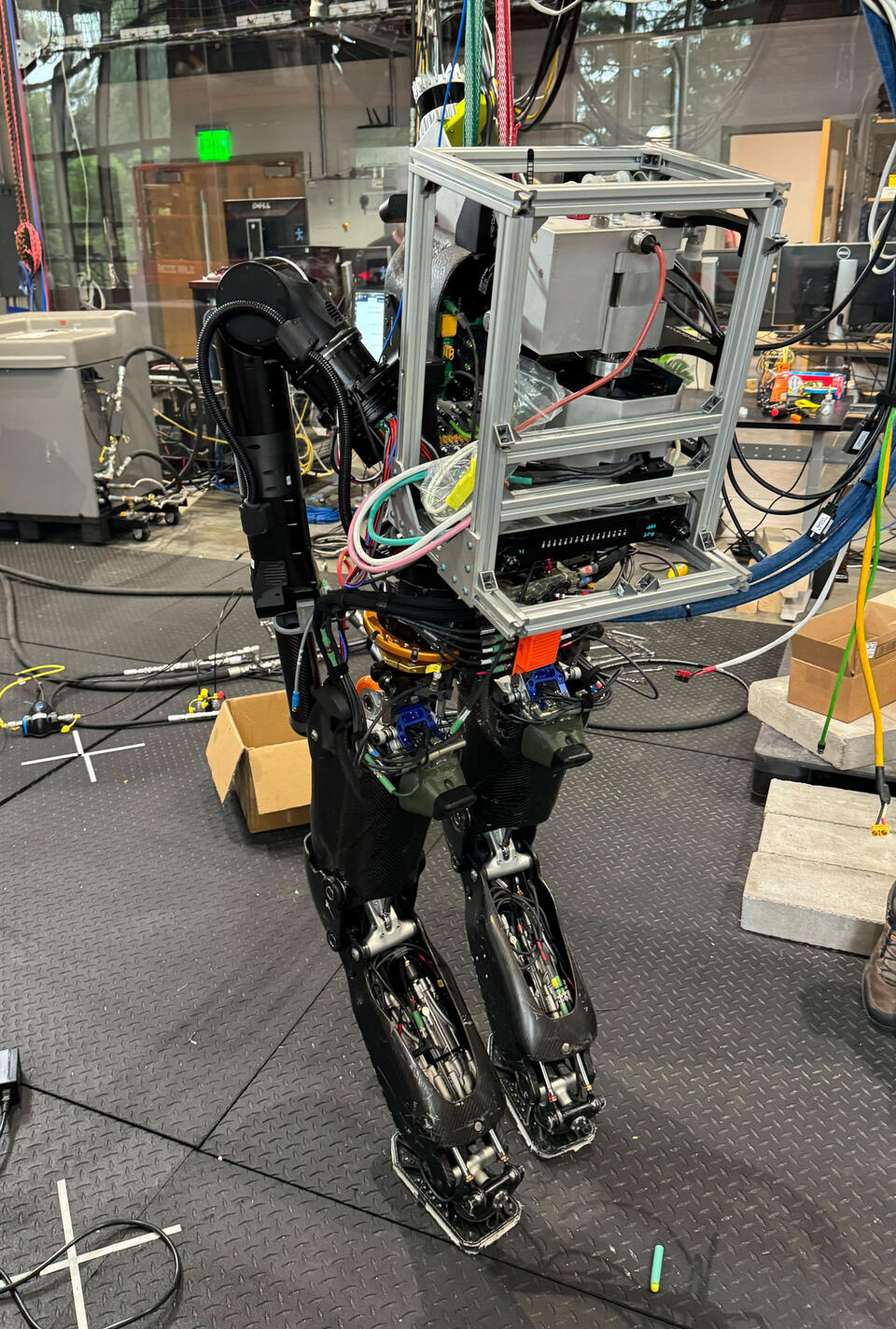

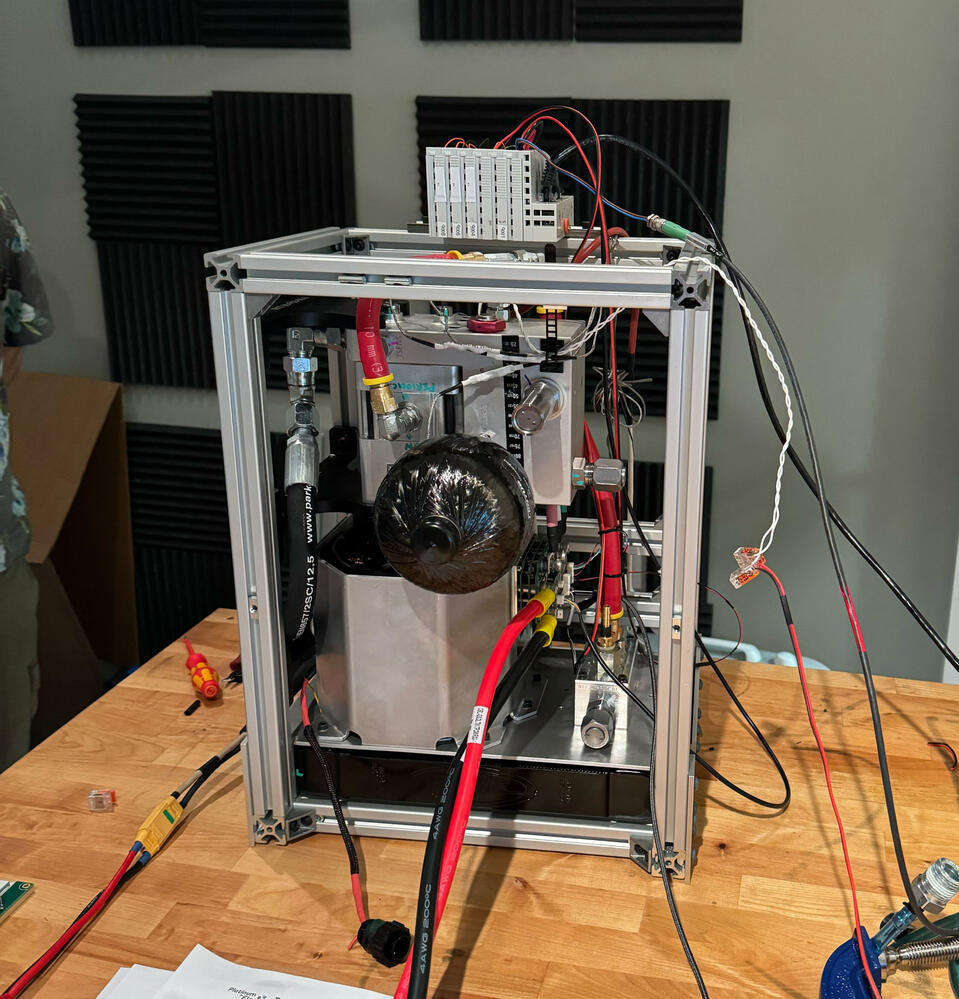

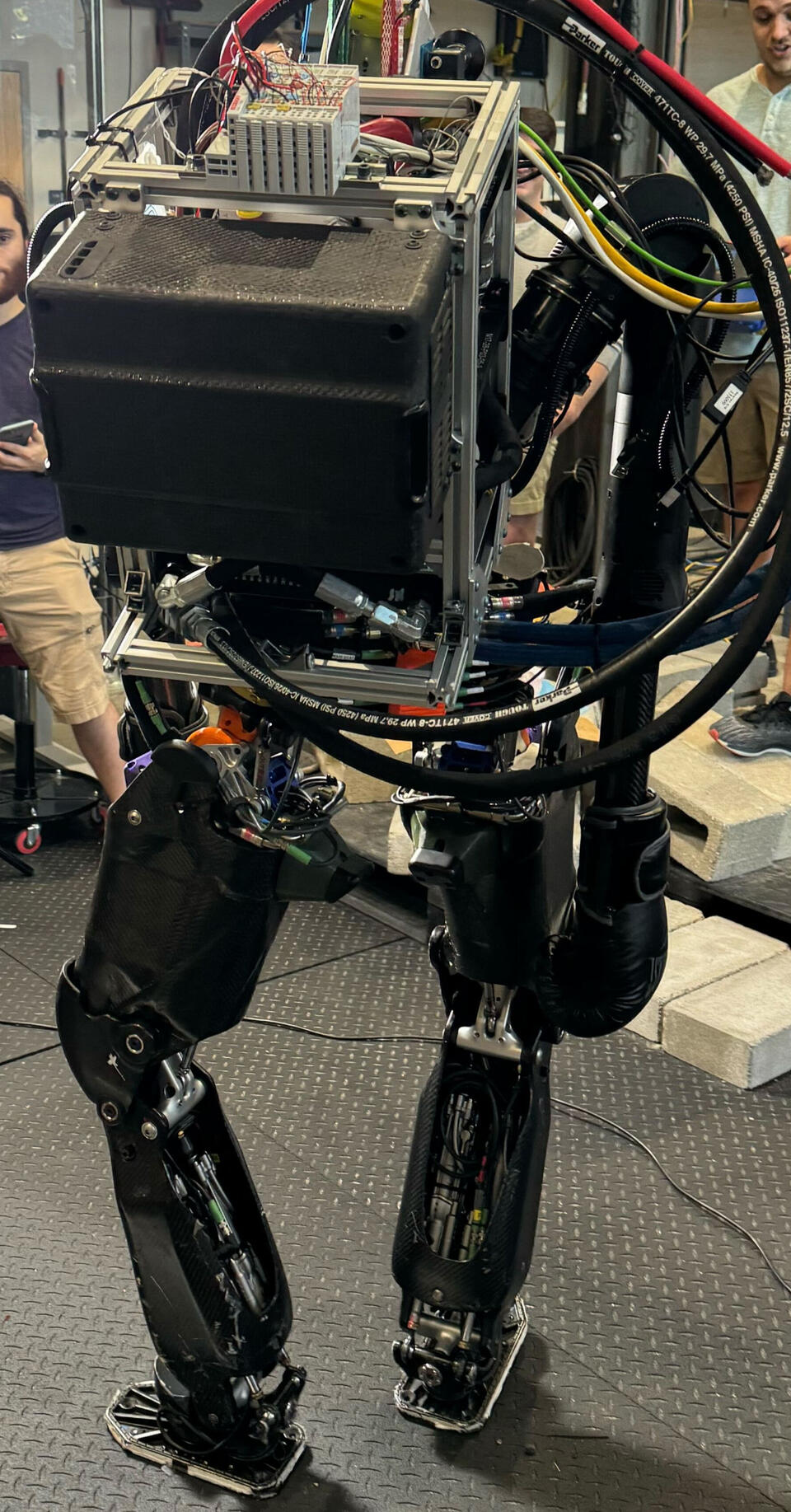

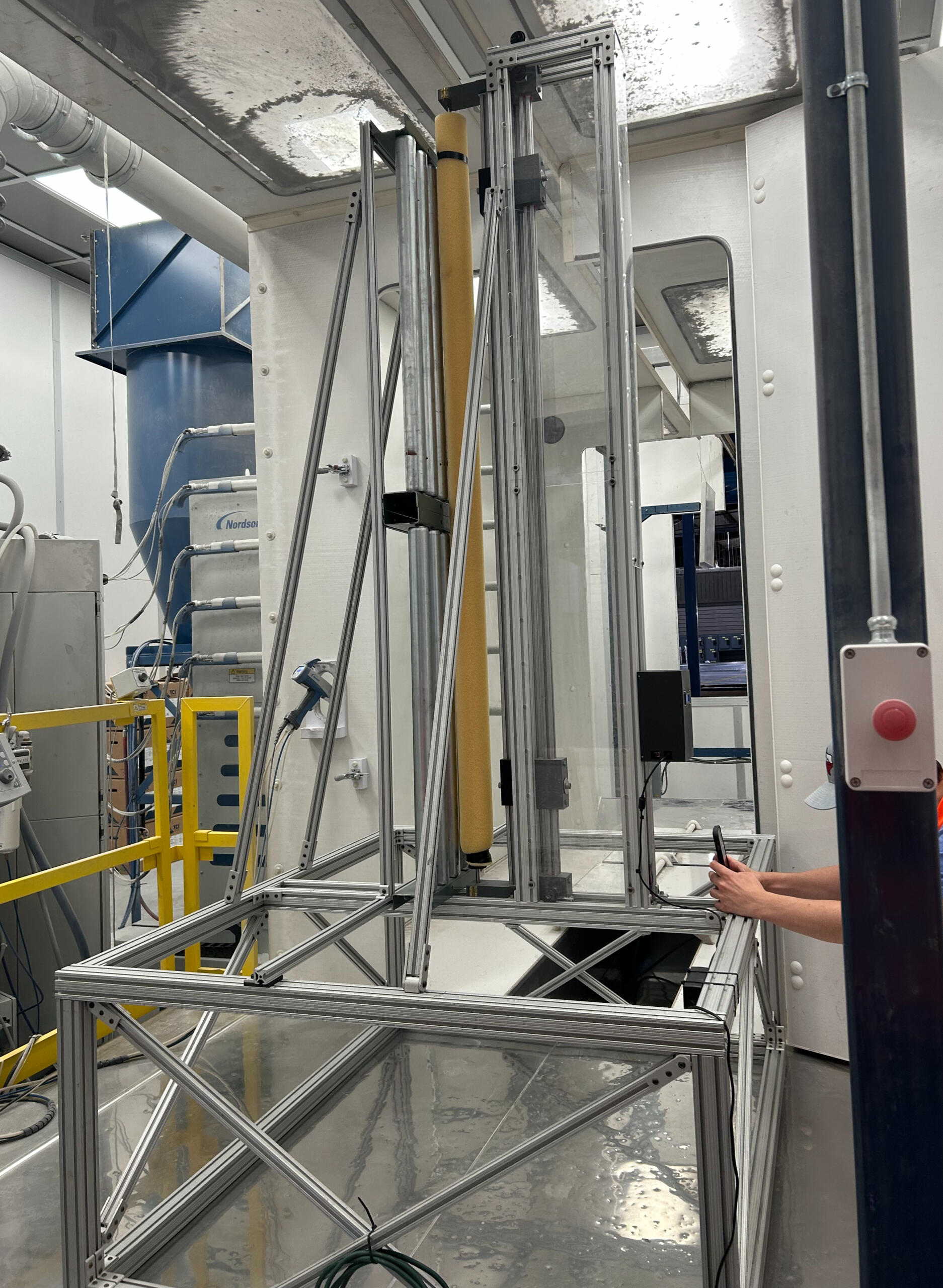

During my second internship with IHMC and Boardwalk Robotics, the Nadia humanoid robot platform was transitioned to a fully onboard hydraulic power unit and battery that were both designed in-house. My task was to design a way to take the hydraulic power unit from the test stand and mount it to the current Nadia torso to begin testing. Eventually, the torso will be redesigned around the hydraulic power unit, but our goal was to get the HPU on the robot and begin testing at full power.The team and I decided that in order to protect the HPU from external damages during operation, we should house it inside a "roll cage". This led to the design of an 8020 extruded aluminum "cage" that housed the HPU. Although it would not be aesthetically pleasing, this was going to be a temporary testing solution until the torso was redesigned in the future. This cage allowed the HPU to be assembled off of the robot and then mounted in one go. This design required intricate manipulation of the hydraulic power unit components in order to package it in the smallest possible space while also leaving room for hose routing. Before the part was finalized, the team decided that we should mount the new onboard battery onto the HPU "roll cage". This required more calculations to ensure that each part would be robust enough to handle the new loading conditions.Below are pictures of the first time the HPU was assembled inside the 8020 cage and mounted for testing on the robot. (Some pictures include the batter on the back)

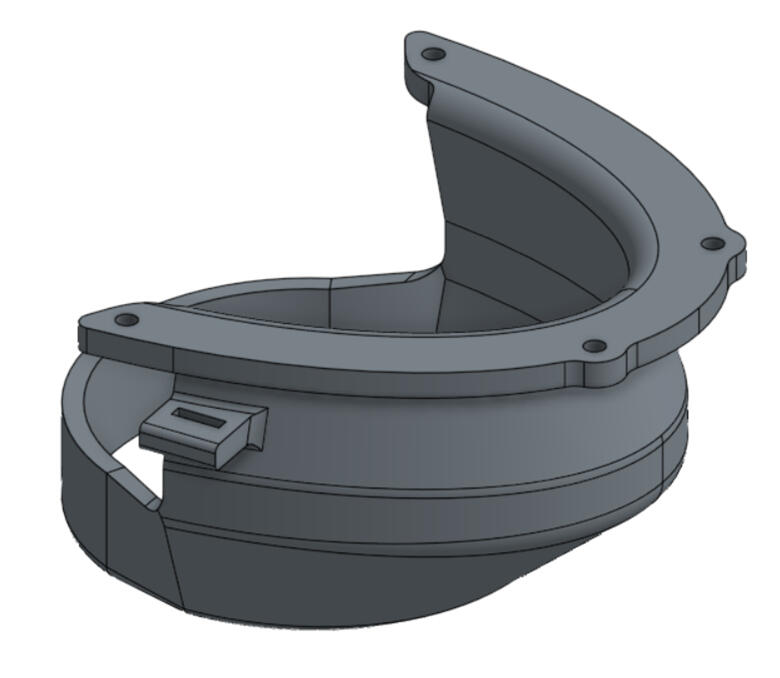

Force Torque Sensor Cover:

I designed a 3D-printed nylon cover that protects the valuable ATI force-torque sensor located in Nadia's foot. This component was carefully engineered to fit around the sensor and to attach to the hard stop located on the top side of the foot. Its design ensures complete protection of the sensor from any potential damage caused by collisions. The protection of sensitive equipment is crucial in the development of humanoid robots.Below are pictures of the design (in OnShape) and the part itself installed on Nadia's foot.

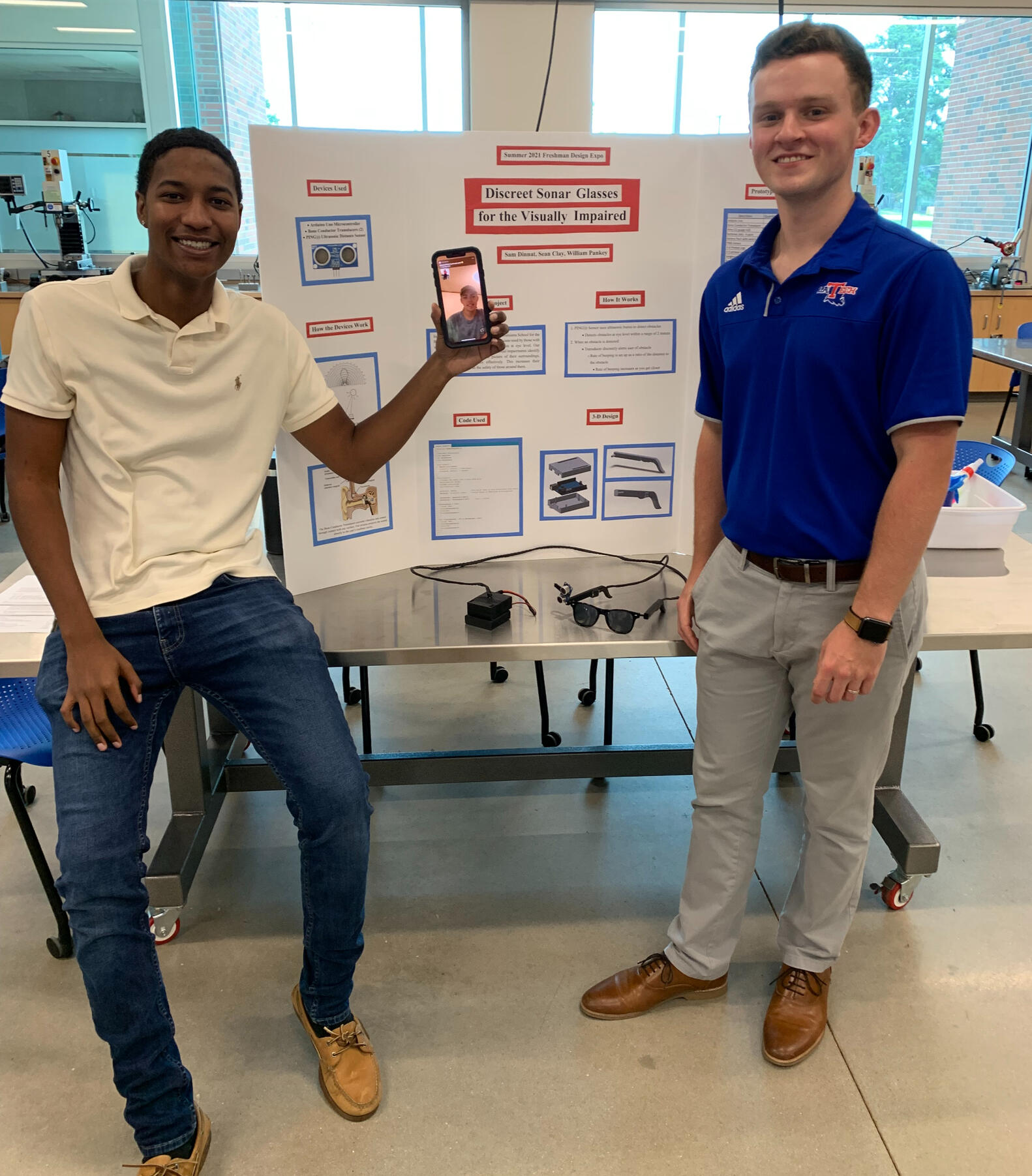

Freshman Design Project

In my freshman year of engineering, my team and I participated in the Louisiana Tech College of Engineering Freshman Design Expo. Our award-winning project was a pair of glasses specially designed to aid individuals with visual impairments in navigation. Our design was judged to be the best overall, taking into account its innovation, functionality, and potential impact on society.

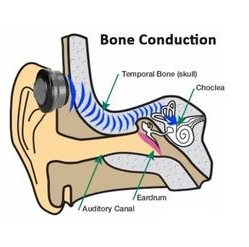

Project Description:

Our team's design project for the Louisiana Tech College of Engineering Freshman Design Expo was a discreet, yet effective solution to help people with visual impairments navigate safely and independently. The glasses we designed contained an ultrasonic distance sensor that detected objects within a certain range. When an object was detected, the glasses produced a tone that only the wearer could hear. To achieve this discreet design, we implanted bone conductor transducers into 3D-printed legs which, when pressed against the ear, converted surface vibrations into a sound that only the wearer could hear. Our goal was to help visually impaired individuals identify obstacles at eye level that would not be identified by a white cane. By doing so, we aimed to improve the safety and independence of visually impaired individuals. We are proud to have won the award for the best overall design and hope that our design will continue to help improve the lives of people with visual impairments.

Senior Design Project

My senior design project was sponsored by Gordon Architectural Systems in Shreveport, Louisiana. Gordon manufactures a broad range of architectural systems and façade components that provide some of the most distinctive finishing touches that can be

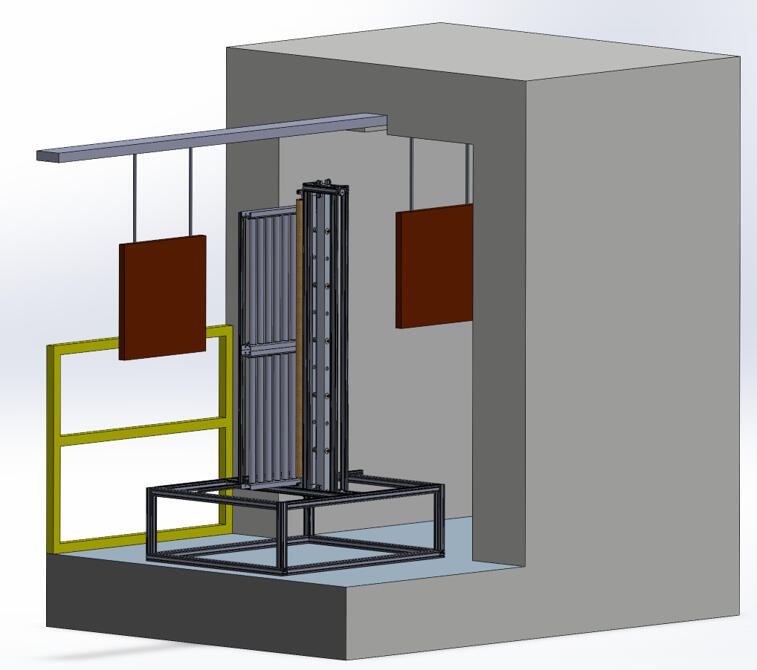

applied to high-end, commercial buildings, and structures. A significant portion of their operations produces panels that are powder-coated with textured finishes.My team designed a mechanism to automate their powder-coat texturing process to achieve a uniform, repeatable finish that also has a realistic weathered look. My team chose this project because it was a challenge that involved multiple engineering disciplines including mechanical design and controls engineering.To adjust for different-sized panels, we implemented an automatic control system that moves the texturing head away from the back panel using two stepper motors.

Fully constructed prototype assembly:

Assembly installed in powder booth:

SolidWorks model of the assembly inside the powder booth:

Senior Design Team pictured with project:

Golf Club Design

This golf club model was created with Solidworks and was based on the design of my personal 7-iron. I was able to replicate the club's specifications and dimensions with precision.

3D Printing

During my time as an intern at IHMC, I constructed a full-scale mockup of the Nadia Humanoid Robot using 3D-printed components. The mockup played a critical role in testing new hardware pieces and prototyping wiring before applying them to the real robot.Included below are images of the mockup. Notably, the left arm (right side of the image) features the newly designed cycloid motor arm, which is much stronger than the older t-motor arm used on the right arm. The left leg is constructed using older carbon fiber shells, while the right leg utilizes 3D printed shells and 3D printed mockup integrated smart actuators (ISAs). The full-scale mockup allowed the team to iterate and refine their designs in a cost-effective manner, minimizing errors and issues when testing the new hardware on the actual robot.

I now own a Prusa i3 MK3S+ and regularly print things that interest me, as well as projects for school.

More Engineering and Robotics Projects

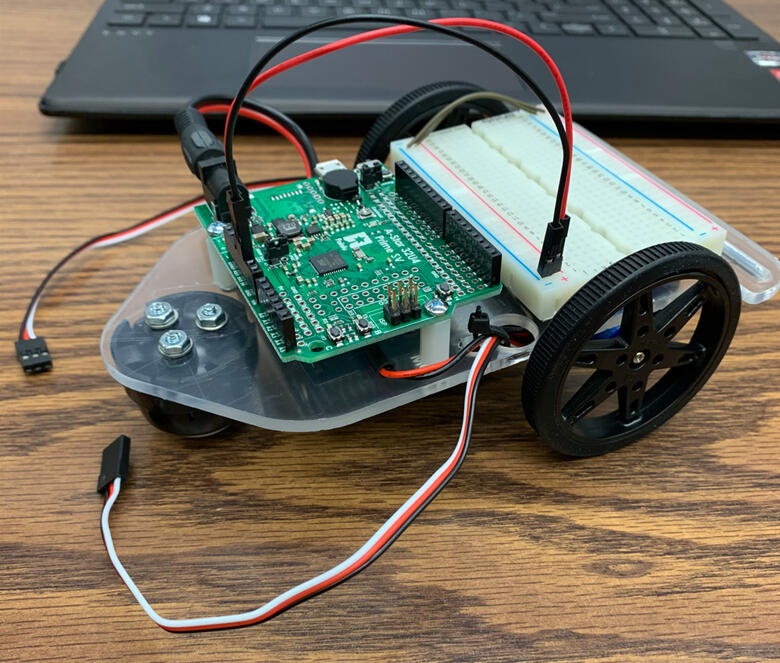

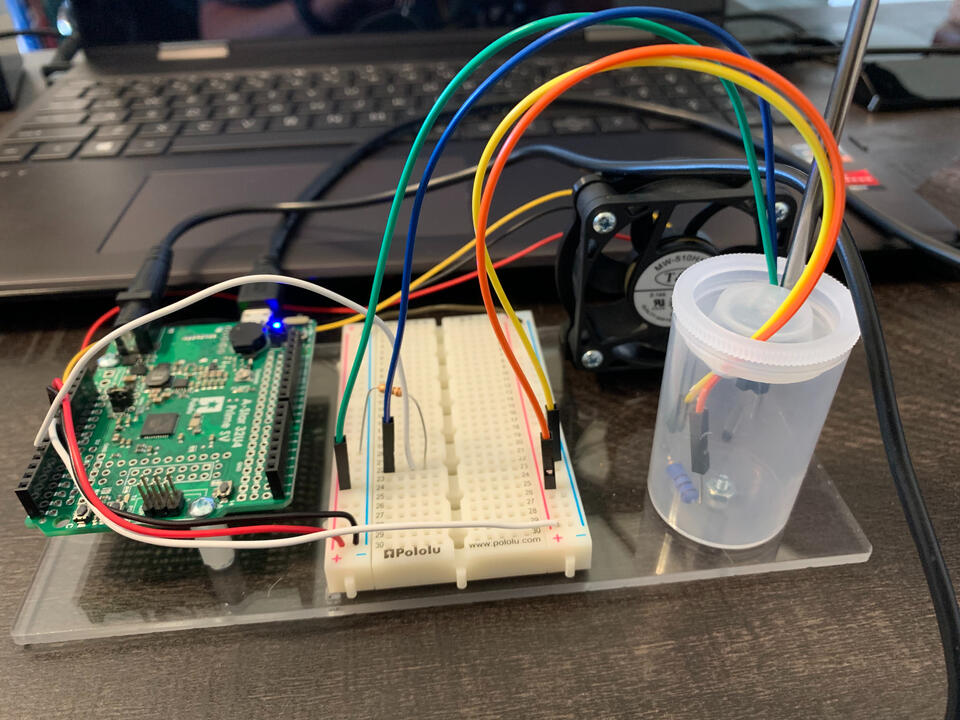

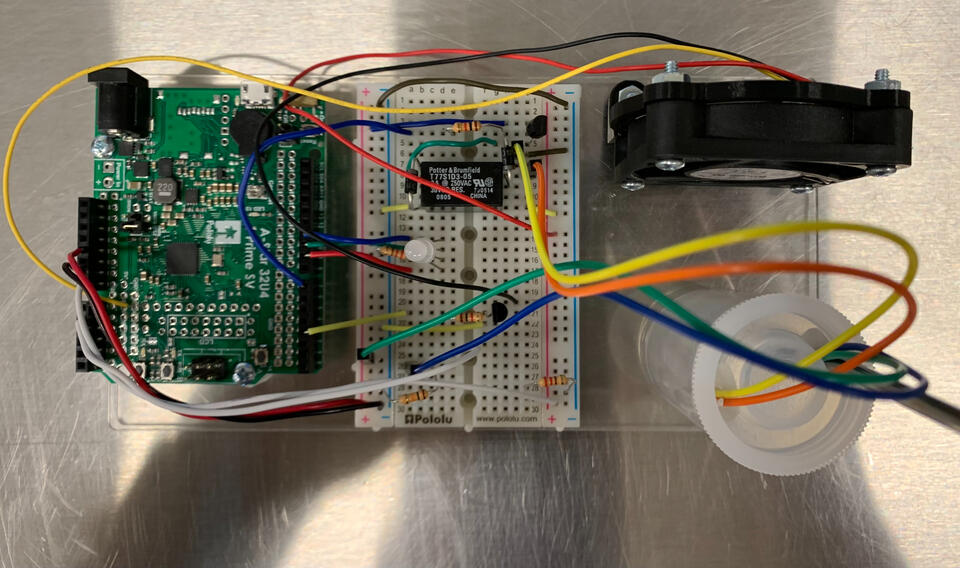

Robotics Platform:During my freshman year at Louisiana Tech, I built a versatile robotics platform utilizing a Pololu A-Star32U4 microcontroller, pictured below. Equipped with two servo-controlled wheels, the platform is capable of responding to various environmental inputs through the integration of multiple sensors. This project allowed me to gain hands-on experience in programming and designing robotics systems, enhancing my knowledge and skills in the field.

Ardunio Film Canister 'Oven':The platform pictured below was also programmed using an A-Star32U4 microcontroller. The platform consisted of a film canister with a large resistor and thermistor inside, a fan, a relay, and a variety of other components and sensors. I programmed this oven to remain within a specified temperature range, and had an RGB led that faded from red to blue depending on the temperature of the oven.

Future Projects

In my continuous pursuit of knowledge, I aim to enhance my skills in mechanical design, fabrication, 3D printing, and programming.I am working on a few projects at this time that I look forward to sharing in the future!

Research

Engineering - Shape Memory Alloys (SMA) and Shape Memory Polymers (SMP)

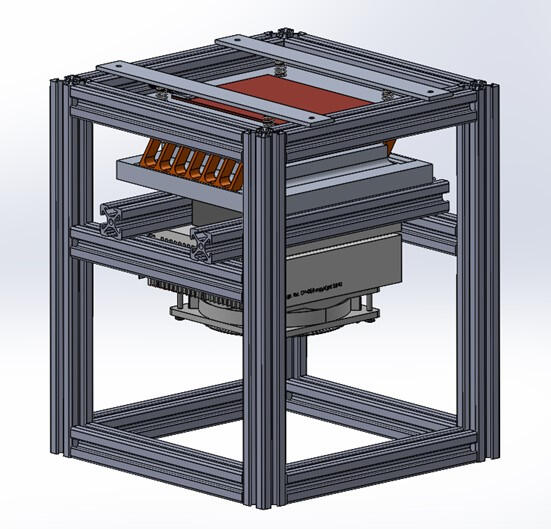

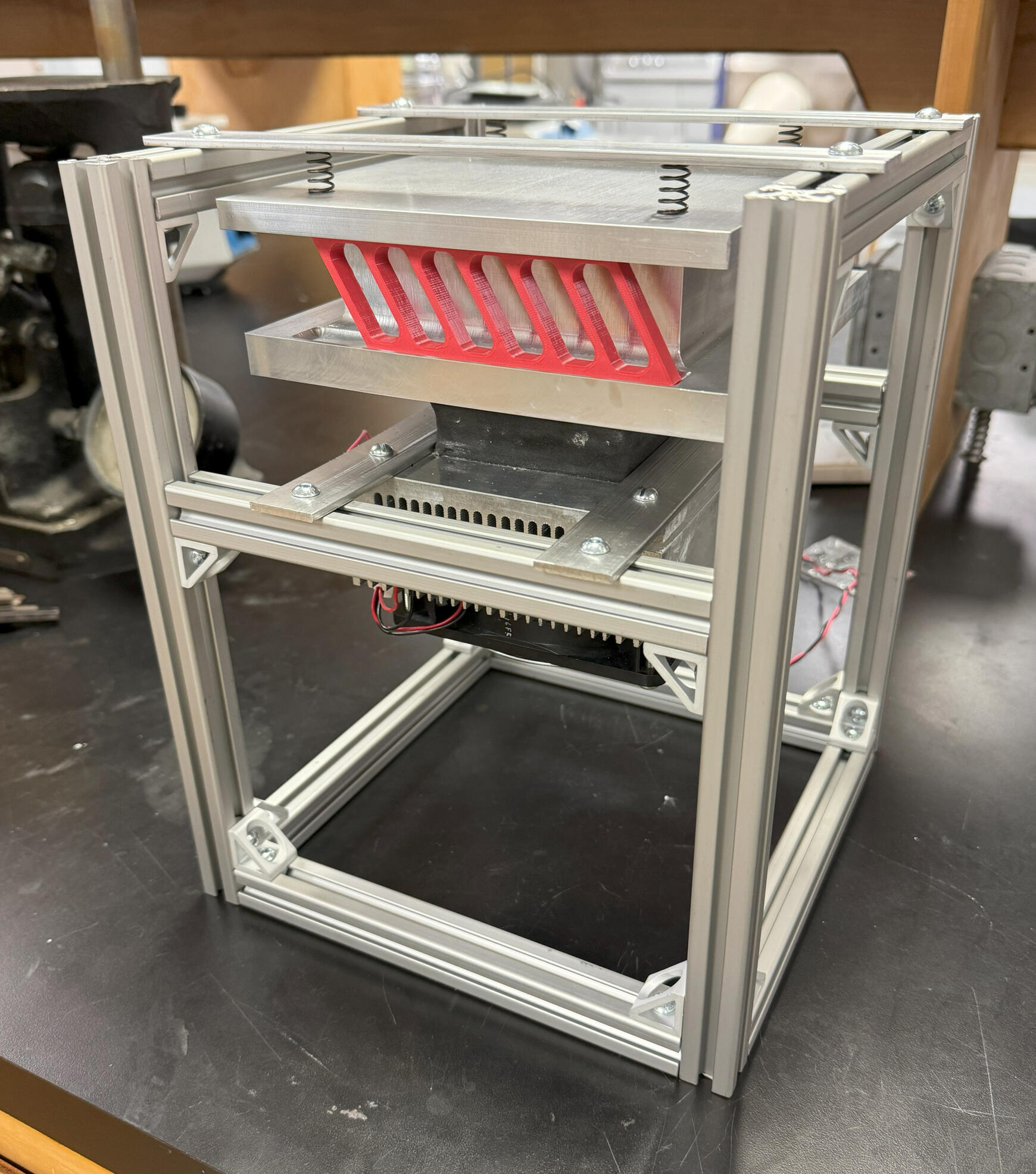

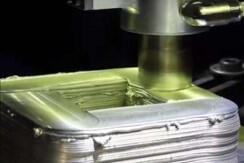

Following the 2022-2023 school year, the professor I was working under left for a different university. I took this opportunity to transition to a more experimental research team. I worked under Dr. Arden Moore in The Multiscale Energy Transport and Materials Laboratory at the Louisiana Tech Institute for Micromanufacturing.In this role, I continued research from a past Master's student on utilizing the shape memory effect exhibited by 3D-printed PLA in a thermal switch. I used the findings from this student's research and construct a completely passive thermal switch using a 3D printed shape memory polymer as the switching device. This research involveed materials science, mechanical design, and thermal design.The initial SolidWorks model, as well as the constructed design, of my thermal switch design is shown below. This design utilizes a lattice style 3D printed shape memory polymer as the primary switching mechanism and custom shape memory alloy springs as a secondary source of contact force.

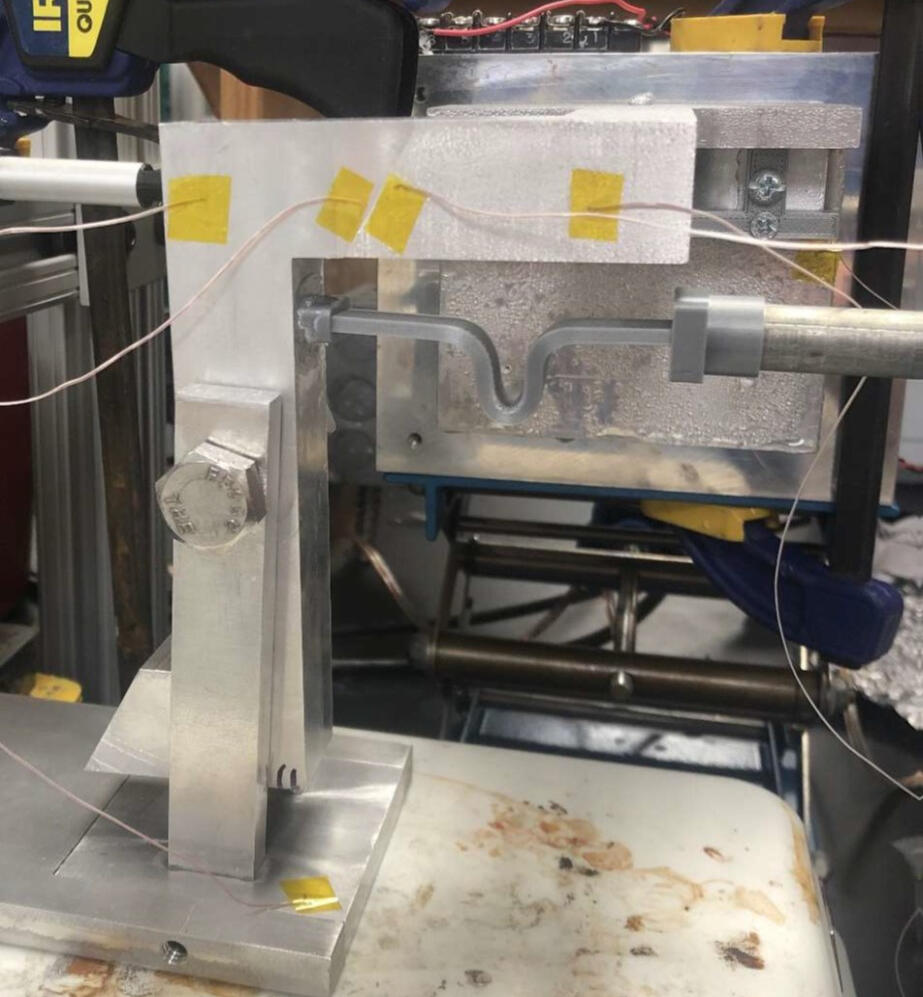

Below is a picture of a thermal switch with thermocouples attached along the conducting region (Barham, 2022). This is one iteration of the previous design.

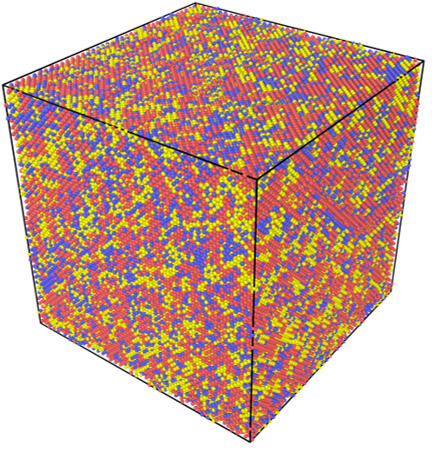

Engineering - Complex Concentrated Alloys (CCA's)

In February 2023, I had the opportunity to present my research on an Atomistic Study of the Plastic Behavior in Complex Concentrated Alloys at the Louisiana Tech Undergraduate Research Symposium. As a result of my presentation, I was chosen to represent Louisiana Tech at the University of Louisiana System Academic Summit. My research aims to develop CCAs that can be used in additive manufacturing through friction stir welding.Abstract:

Complex Concentrated Alloys (CCAs) with multiple elements mixed in high mole fractions are a new class of alloys that offers large compositional space in materials design. State-of-the-art research has observed CCAs with potentially superior mechanical properties. However, the fundamental understanding of the hardening mechanisms that are largely determined by the dislocation behaviors and their interaction with microstructures is still lacking. In this work, by using Molecular Dynamics simulations, uniaxial tensile straining is applied to the single-phase and dual-phase CCAs with embedded atom method (EAM) interatomic potential using open-source MD code LAMMPS. Simulation results show the details of the dislocation evolution and its interaction with phase interfaces, as well as their effect on the mechanical hardening, which provides important fundamental mechanistic understanding and insight into the structural design and materials processing of CCAs, which have potential uses across many different industries.

Economics

In the Winter Quarter of 2018-2019, I conducted research on the potential impact of Excess Reserve Policy on the Volatility of Interest Rates. As a result, my paper was chosen for presentation at the Economic Scholar's Program held at the Federal Reserve Bank of Dallas. In April 2019, I presented my findings at the conference. Below, you can find the research question and abstract for the paper.Research Question:

What portion of the volatility of the interest rate can be attributed to excess reserve policy? Does including this relationship as an exogenous variable make other macroeconomic forecasts better?Paper Abstract:

The relationship between excess reserves and the effective federal funds rate has not been studied extensively since the Federal Reserve began paying interest on reserves in October 2008. This research finds what portion of the volatility of the interest rate can be attributed to excess reserve policy. Using this, the analysis found that some macroeconomic variables forecasts can be made better by including the estimated interest rate volatility from excess reserve policy as an exogenous variable. These findings will contribute to the literature base by adding a more in-depth understanding of excess reserve policy, and how that can be used to create better macroeconomic forecasts. The results could have several monetary policy implications.